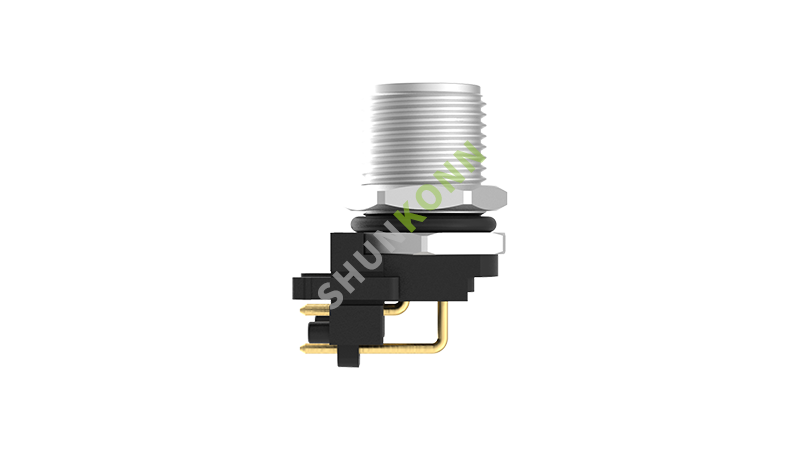

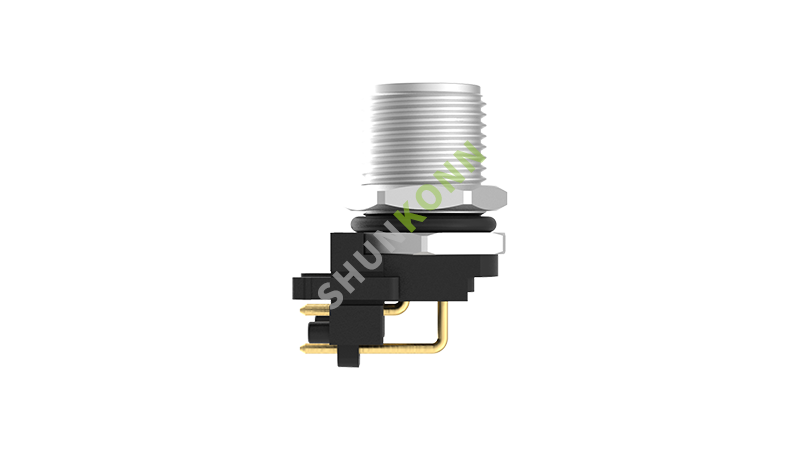

M12 Circular connector troubleshooting solution

Because of its compact design and high reliability, the M12 circular connector is widely used in industrial automation, sensors and communication equipment. However, in long-term use or harsh environments, the connector may fail. The following lists common faults and their solutions to ensure the stable running of the device.

1.For poor contact problems

- Inspection and cleaning: Use a non-corrosive cleaner to remove oxides or dirt from the terminal surface.

- Correct or replace the terminal: Correct the bent pin and replace the terminal if it is seriously damaged.

- Regular maintenance: Check the contact of the insertion and removal parts regularly to avoid excessive wear.

2.For seal failure

- Replace the seal ring: Choose a high-quality rubber seal ring and ensure that it meets the requirements of the protection class (such as IP67, IP68).

- Reinstall: Follow the correct steps to install the connector, ensuring that the seal rings fit tightly to the housing.

- Choose weather-resistant materials: In corrosive environments, a connector with corrosion resistance is preferred.

3.For mechanical damage problems

- Check the integrity of the shell: If cracks or damage are found, replace the shell or connector in time.

- Avoid excessive force: When wiring the device, plan the cable direction properly to avoid pulling or excessive bending.

- Selection of high-strength materials: For high-impact scenarios, choose metal shells or reinforced connectors.

4.For signal interference problems

- Optimize the shield design: Check the integrity of the shield layer and replace the shield cable or connector if necessary.

- Reasonable wiring: Separate signal cables from high-voltage cables to reduce crosstalk.

- Strengthen grounding: Ensure that the shielding layer is effectively grounded to reduce the impact of electromagnetic interference.

5. Maintenance suggestions to prevent faults

Regular inspection:

- Periodically test connectors for electrical properties such as contact resistance and insulation resistance.

- Check whether the shell and sealing ring are in good condition, and replace the aging parts in time.

Correct operation:

- Avoid rough insertion and removal, and correctly align the keys for connection.

- Use the recommended torque during installation to prevent over-tightening or over-loosening.

- Select the right connector

- According to the application environment, select the appropriate level of protection, corrosion resistance and mechanical strength of the connector.

- In high-interference scenarios, shielded connectors are preferred to ensure signal stability.