Application of circular connector in robot

SHUNKONN has 10 years of experience in the connector industry and is committed to providing superior connectivity solutions.

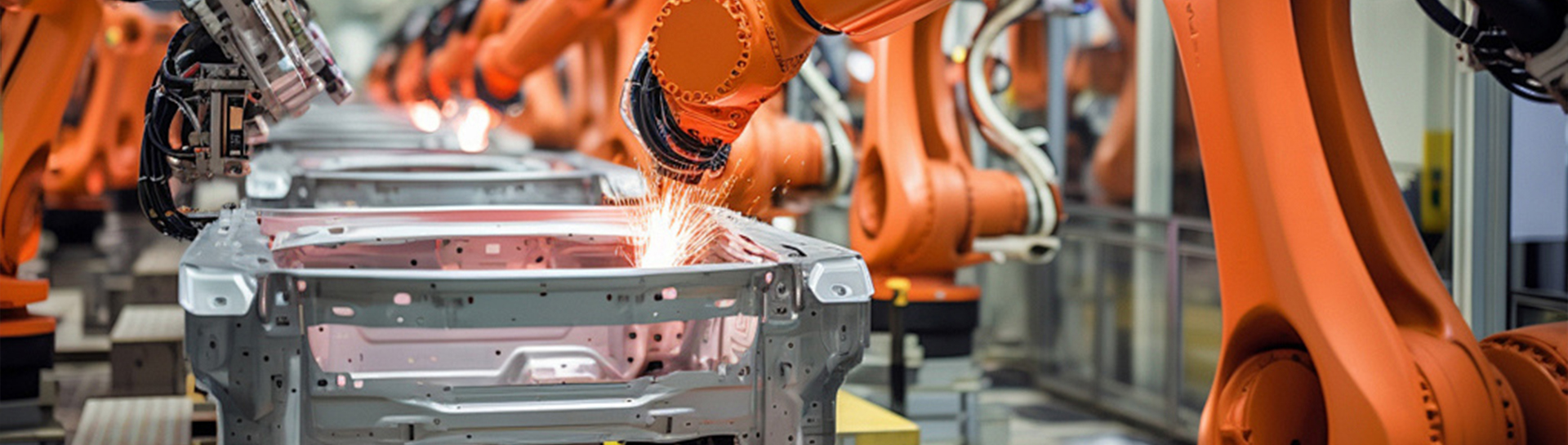

In the context of the rapid development of intelligent manufacturing and automation technology, industrial automation is playing an increasingly important role in the manufacturing industry, and industrial robots, as the core of automated production lines, show excellent efficiency, precision and reliability. As industrial robots move toward higher motion beats, higher precision, higher load carrying capacity, and more compact structures, signal transmission between servo motors, sensors, and control systems becomes critical. In this process, the circular connector has gradually become an indispensable key component.

The circular connector can adapt to complex working environments, with excellent anti-interference ability and protection performance, to ensure the efficient and safe operation of the robot system under high load and dynamic conditions. They not only support the stable transmission of power and signals, but also optimize the overall performance of the robot, meeting the needs of modern industry for flexibility and reliability.

SHUNKONN focuses on the development of high-performance circular connectors and is committed to providing comprehensive connectivity solutions to help users achieve efficient operation in various robot applications. In harsh production environments, the reliability and durability of circular connectors make them an important factor in promoting industrial upgrading, significantly improving production efficiency and reducing operating costs.

SHUNKONN will continue to innovate in the field of high-performance connectivity, improve product performance and reliability, help customers succeed in industrial robot automation production, and accelerate the process of intelligent manufacturing. By continuously optimizing the connection technology, circular connectors will play a greater role in robotics applications and promote the future development of industrial automation.

Robot requirements for circular connectors

For robots, customers may face the following pain points when using circular connectors

Pain points in robot connections

underdurability

Robots are often exposed to high vibration and shock environments, and connectors can be damaged due to improper materials or design, affecting the long-term reliability of the system.

Signal interference

In a complex electromagnetic environment, the anti-interference performance of the connector is insufficient, which may lead to signal loss or error, affecting the control accuracy and data transmission of the robot.

Inadequate protection

Many industrial applications require connectors with high levels of protection (e.g. IP67/IP68) against moisture and dust intrusion. Inadequate protection levels can cause connectors to fail in harsh environments.

Installation and maintenance are complex

The installation and disassembly process of some connectors is cumbersome, and the lack of fast connection design leads to prolonged on-site maintenance time and affects production efficiency.

Insufficient electrical carrying capacity

In high power applications, connectors may not meet current and voltage requirements, resulting in overheating, failure, or system downtime.

Size and compatibility issues

The variety of robot designs and the lack of flexibility in the size and pin configuration of connectors can lead to incompatibility with existing equipment, thus limiting system integration.

Cost control challenge

High performance connectors are usually expensive, and customers face the pressure of cost control while pursuing quality and performance, affecting the overall project budget.

SHUNKONN Technology Solutions

As a specialist manufacturer of circular connectors, SHUNKONN offers the following effective solutions to the pain points faced by robots when using circular connectors:

Material innovation

High-strength, corrosion-resistant materials, such as aluminum alloys and engineering plastics, are used to enhance connector durability and adaptability, thereby increasing reliability in harsh environments.

Improved shield design

Multi-layer shielding technology is introduced to effectively reduce electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the stability of signal transmission and data integrity.

Optimized sealing structure

The advanced seal design increases the protection level to IP67/IP68 to prevent the intrusion of water and dust and ensure the normal operation of the connector in wet and dusty environments.

Fast connection mechanism

Design quick connection and disconnection mechanisms to simplify installation and maintenance processes, reduce equipment downtime, and improve work efficiency.

High current carrying capacity

Through improved electrical design and materials, the current carrying capacity of the connector is increased to ensure safe and stable operation under high load conditions.

Modular design

The implementation of modular design makes the maintenance and replacement of connectors more flexible, and customers can easily replace specific modules according to their needs, reducing maintenance costs.

Intelligent monitoring function

Intelligent monitoring technology is integrated to check the connection status in real time and provide fault alarm function to help customers identify and solve potential problems in a timely manner.

Environmental adaptability test

Rigorous environmental adaptability testing ensures that connectors operate reliably in extreme temperature, humidity and chemical environments.

Customized service

Provide customized solutions to adapt the design and function of connectors according to the specific needs of customers to meet the application of different industries.

SHUNKONN is committed to solving the pain points faced by customers when using circular connectors to improve the overall performance and reliability of products.

Dedicated to applying the latest technologies to products to improve performance and reliability

Contact us for a quick quote and get free technical answers from our technical team.

You can also contact us directly in the following ways: visit, telephone, email