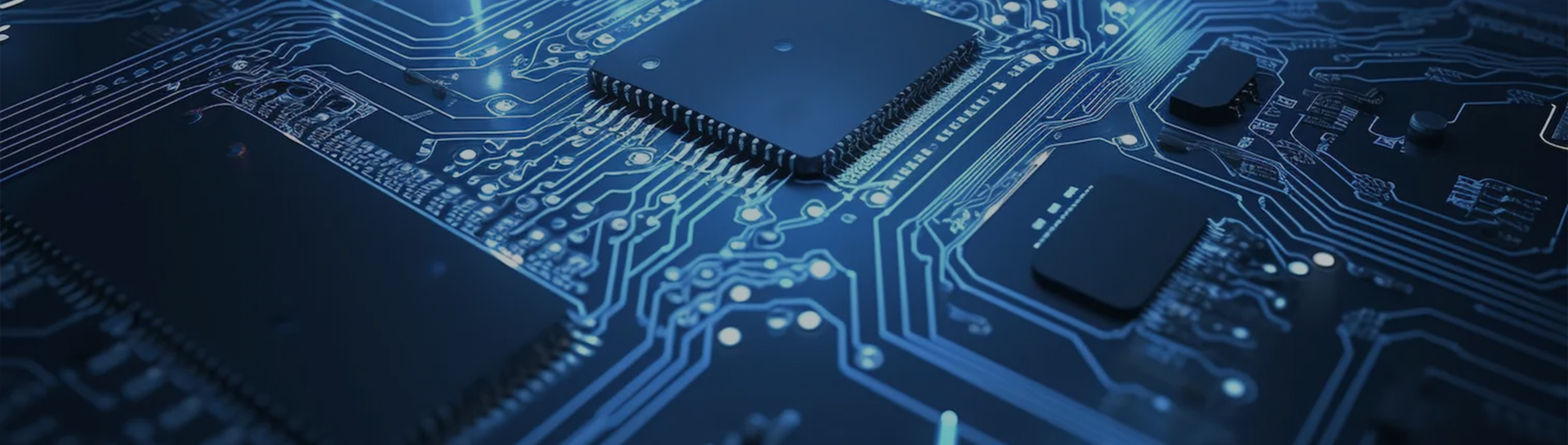

Application of circular connector in communication equipment

SHUNKONN has 10 years of experience in the connector industry and is committed to providing excellent connectivity solutions.

In the context of the rapid development of intelligent manufacturing, the role of industrial communication equipment is becoming increasingly important. With the advance of Industry 4.0, the demand for efficient, reliable and secure communication solutions is increasing. These devices not only deal with massive data, but also ensure real-time information transmission and system stability.

SHUNKONN focuses on the development of high-performance industrial communication equipment and provides comprehensive connectivity solutions to help customers achieve intelligent upgrades, improve production efficiency and reduce operating costs. We will continue to promote technological innovation, improve product performance and reliability, help customers succeed in the era of intelligent manufacturing, and promote the future development of the industry.

Requirements for circular connectors in the field of communication

For communication devices, customers may face the following pain points when using circular connectors

Pain points in communications

Stability of high-speed data transmission

In high-speed data transmission applications, circular connectors may experience reduced signal integrity. As transmission rates increase, electrical characteristics inside connectors such as insertion loss, return loss, and crosstalk become more important. Attenuation and reflection of the signal can lead to packet loss or error, especially in areas such as real-time data streaming, high-definition video transmission, and industrial automation control, and this instability can have serious consequences. SHUNKONN circular connectors are designed to optimize these electrical characteristics to improve reliability for high-speed transmission.

Electromagnetic compatibility and anti-interference issues

Electromagnetic compatibility (EMC) and anti-interference capability are key factors to ensure the reliability of communication systems. Circular connectors may not provide adequate shielding in electromagnetic interference (EMI) environments, resulting in external interference to the signal and weakening the reliability of data transmission. Especially in high-frequency applications, SHUNKONN connectors are designed with full consideration of shielding, grounding, filtering and other measures to reduce the impact of interference and ensure the stable operation of the system.

Durability and reliability problems caused by frequent use

In high frequency plug-out applications, the durability and reliability of circular connectors are severely tested. Mechanical wear, contact point oxidation, metal fatigue, etc. caused by repeated insertion and removal may lead to poor contact, which in turn affects the stability of signal transmission. SHUNKONN connectors use highly wear-resistant materials and optimized contact point construction for increased reliability in high-cycle environments.

Inadequate protection

The protection levels of many circular connectors (such as IP levels) are not sufficient to deal with extreme environmental conditions. The performance of connectors in terms of water, dust and corrosion protection may not meet the needs of some industrial applications. For example, in the Marine, mining, chemical and other industries, connectors are exposed to salt spray, chemical corrosion and extreme temperatures, which can easily lead to equipment failure and signal interference, affecting the overall reliability of the system. SHUNKONN is committed to providing connectors with high levels of protection to adapt to these harsh environments.

Compatibility problem

Circular connectors from different manufacturers may differ in standards and specifications, resulting in limited interconnections between devices. Compatibility issues not only add complexity to system integration, but can also lead to additional costs during maintenance and upgrades. SHUNKONN connectors are designed and produced in accordance with industry standards, ensuring seamless connectivity between all types of devices, thereby increasing system efficiency.

SHUNKONN Solutions

As a professional manufacturer of circular connectors, SHUNKONN offers effective solutions to the pain points faced when using circular connectors for communication products:

Improved circular connector design

Improve signal integrity by optimizing electrical characteristics, such as reducing insertion losses and return losses. Use advanced analog and digital design tools to ensure connector reliability under high-speed transmission conditions.

Enhanced durability

Select highly wear-resistant materials and improved contact design to minimize wear caused by frequent insertion and removal. Rigorous durability testing ensures that connectors maintain stable performance in high-cycle environments.

Waterproof and dustproof design

Enhanced connector protection, such as IP67 or higher, to ensure that the connector will work properly in wet, dusty or corrosive environments. Use designs such as seals and shields to enhance water and dust resistance.

Easy to install design

Designed to simplify the process of installing and removing connectors and reduce reliance on dedicated tools. The introduction of fast connection technology and clearly marked plug/socket design have improved user convenience and accuracy.

Cost optimization and supply chain management

Reduce production costs while maintaining product quality through lean manufacturing and optimized supply chain management. Establish a stable supply chain to ensure timely supply of materials and overall production efficiency.

Provide professional technical support and after-sales service

Provide comprehensive technical support to customers, including product selection, installation guidance and troubleshooting. At the same time, establish a perfect after-sales service system to ensure that customers get timely help and solutions in the process of use.

Dedicated to applying the latest technologies to products to improve performance and reliability

Contact us for a quick quote and get free technical answers from our technical team.

You can also contact us directly in the following ways: visit, telephone, email