Why choose us

Shunkonn Teachnology has a strong R & D team that can quickly respond to customer custom needs and meet various complex application scenarios. We are committed to responding to customers' customized requests in a short time to ensure rapid delivery. We are committed to providing reliable connection solutions through continuous technological innovation and strict quality control to support technological progress and development of various industries.

Factory strength

Shunkonn focuses on the development and customization of connectors, and has experienced experience in the design and implementation of industrial automation systems in 10 years. As a professional connector supplier, we focus on providing high -performance connection solutions covering control systems, sensors, actuators, and data communication to help customers improve operating efficiency.

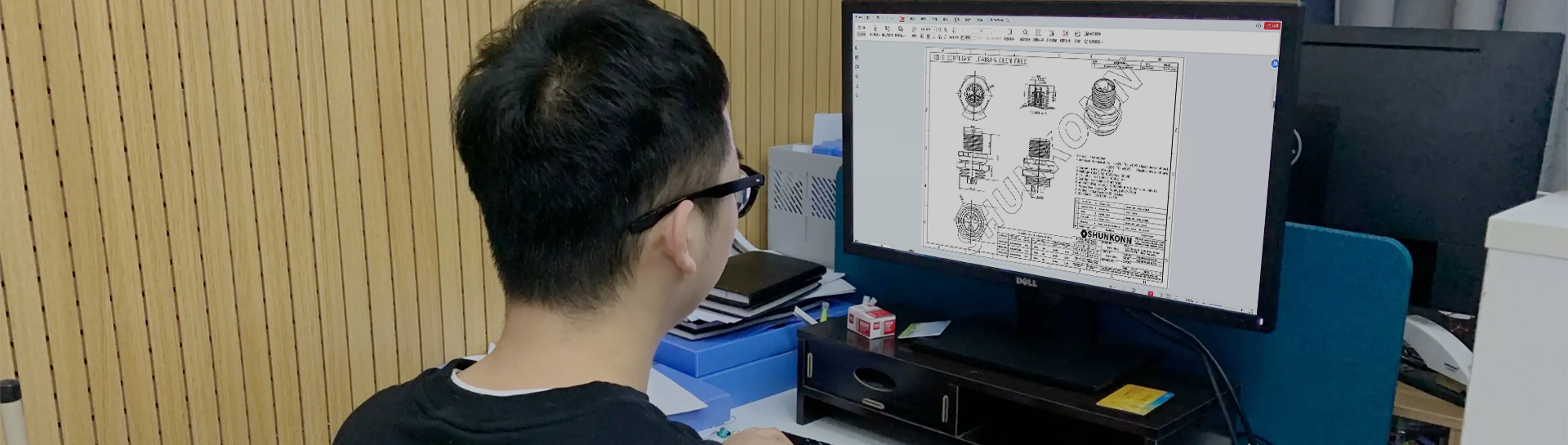

The R & D team has rich experience in product development.

Efficient manufacturing processes and strict test verification are adopted. Ensure product quality and delivery on time.

Technical support provides customers with timely technical consultation and problem solving.

The comprehensive strength we are developing, production, quality management, marketing, and customer support ensure that we can meet the diverse needs of customers and promote their success and industry development.

10

Industry experience

3000

Factory area

10

R & D team

50

Design patent

Main product

Customization

Customization capabilities of circular connectors in industrial automation. Through closely cooperating and communication with customers, we provide professional solutions to effectively solve specific technical challenges, improve equipment performance, reliability and economics, and promote customer business success.

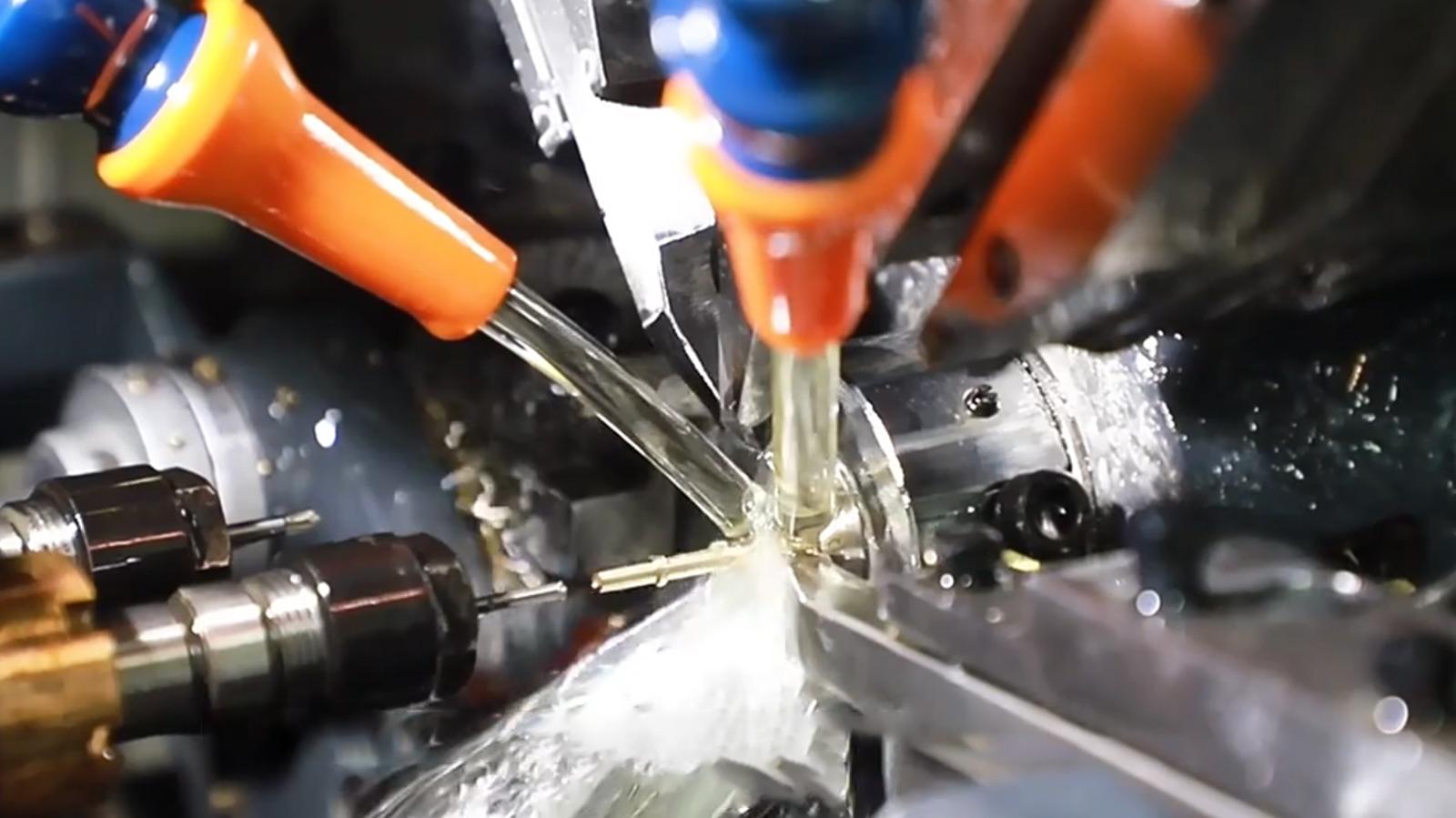

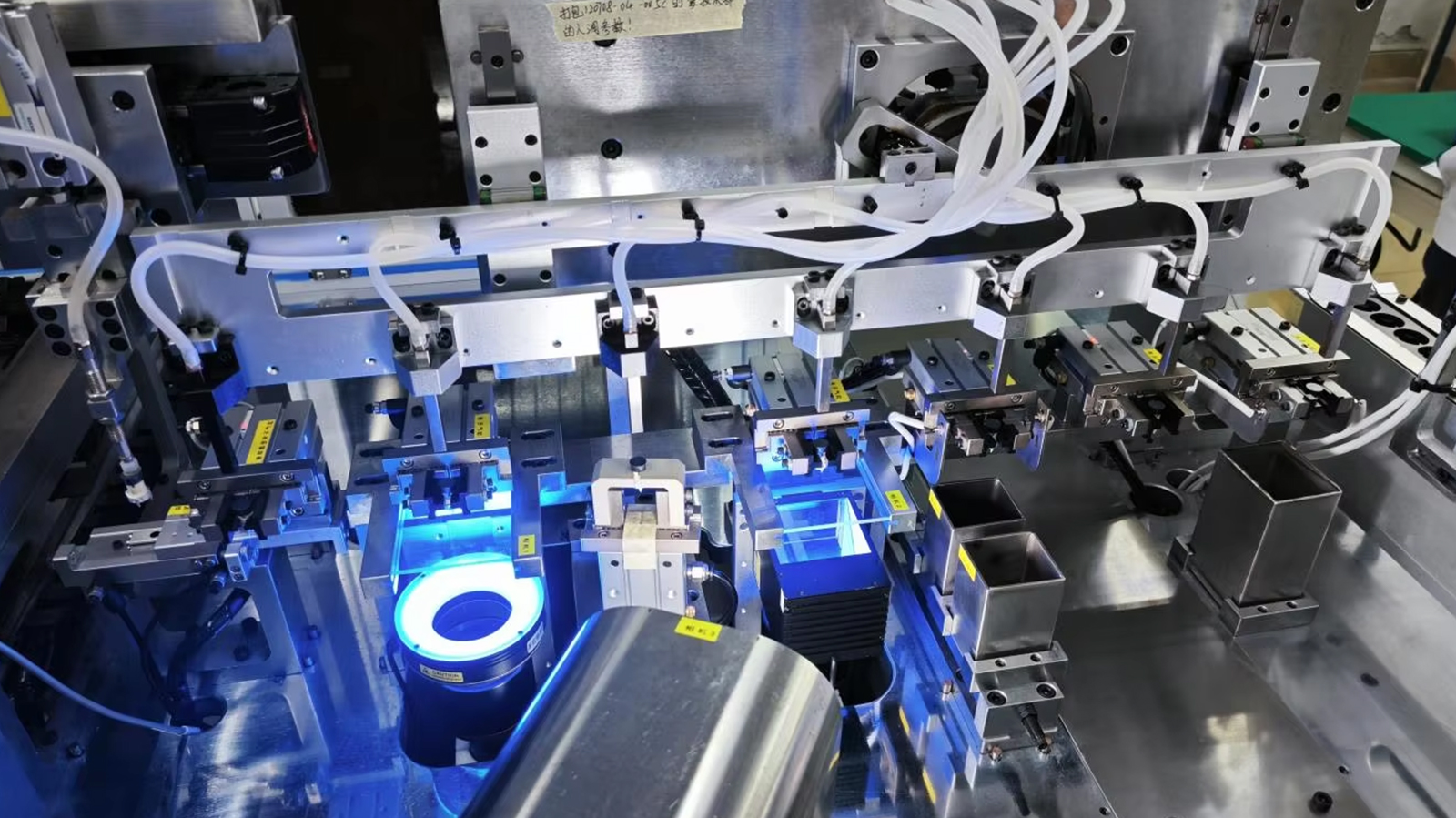

Production equipment

The use of advanced equipment and technology in the production of circular connectors can ensure product quality, improve production efficiency, carry out technological innovation and strict quality control.

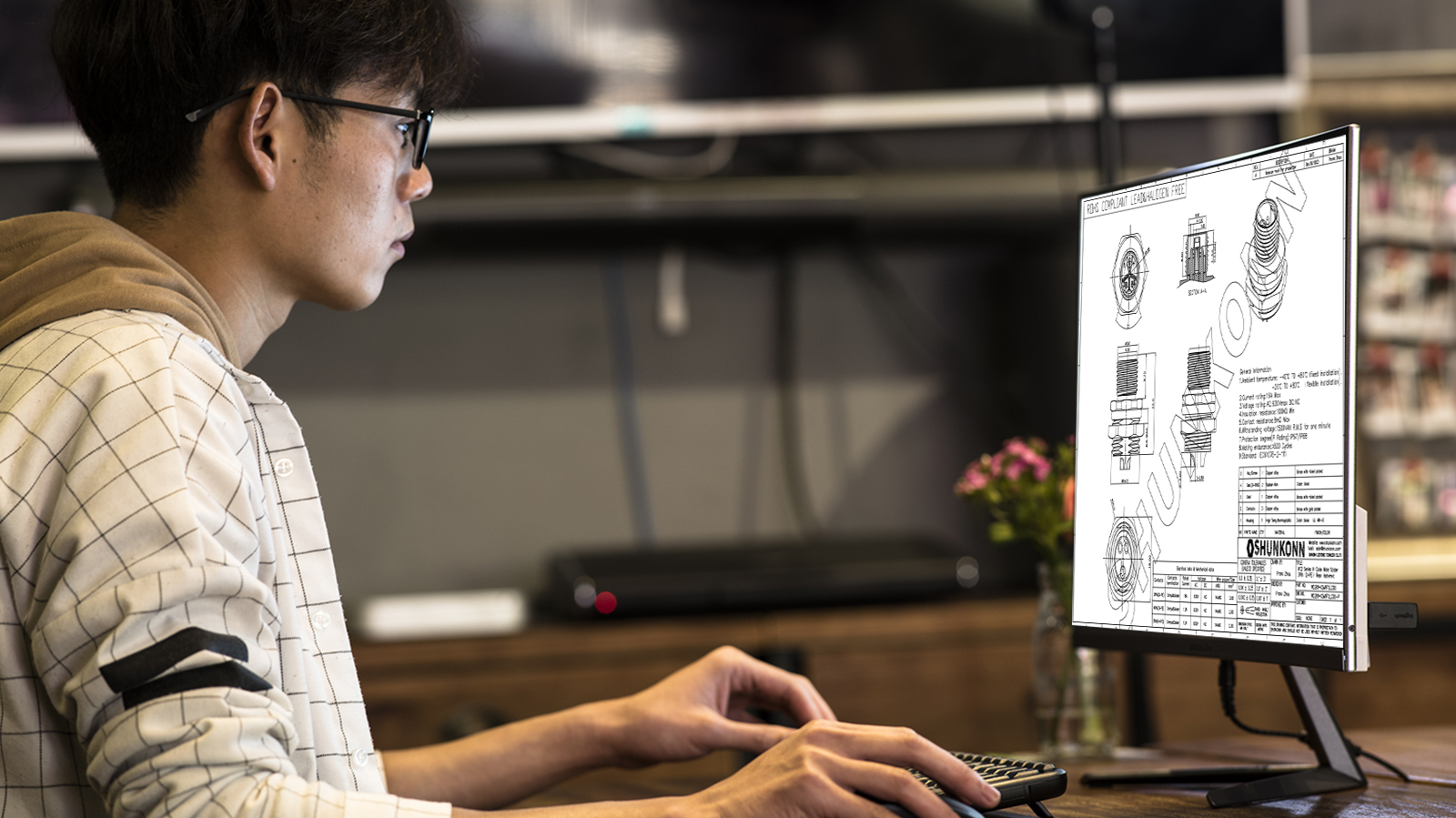

Design process

01 Demand collection and analysis

Communicate with customers to understand application scenarios, functions and technical requirements. Analyze and use the environment to ensure that the design meets the application conditions.

02 concept design

Preliminary design plans are formulated according to customer requirements, including sizes, shapes, materials and fixed methods. The review plan is to ensure feasibility and innovation, and adjust according to customer feedback.

03 Detailed design

Make electrical and mechanical design to ensure the performance and strength of the connector. Use CAD software modeling and simulation to verify the rationality of the design.

04 prototype production

Use additive manufacturing or CNC processing for fast prototypes to test and evaluate performance.

05 test and verification

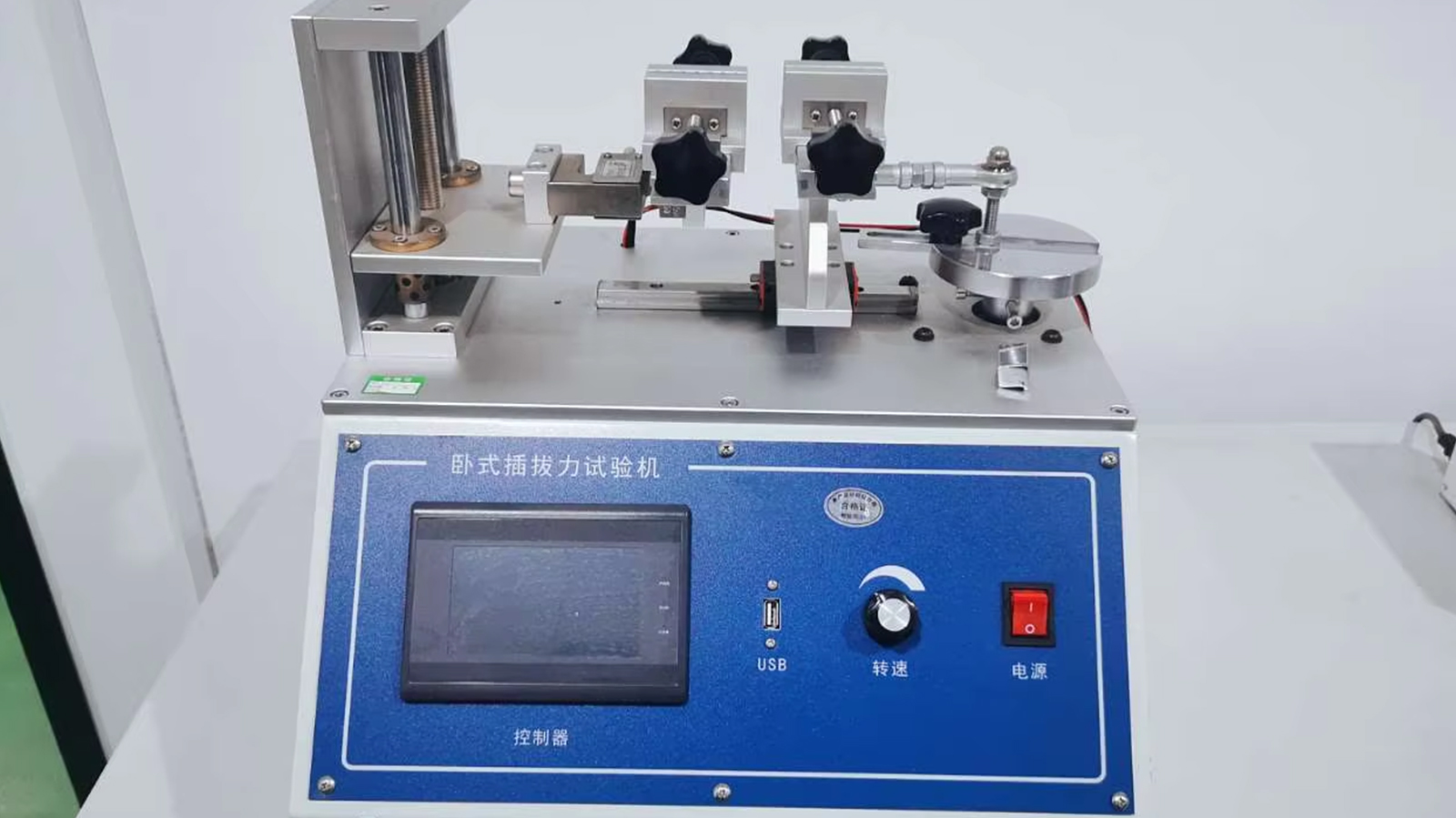

Formulate test plans, including environmental and electrical performance tests. Execute testing and analyze data to ensure the reliability and stability of the connector.

06 Production preparation

Formulate the production process to optimize production, ensure that the materials meet the standards, and perform quality control.

07 mass production implementation

Monitor the production and adjust the parameters to ensure that the product quality is consistent. The international standard quality management system is adopted to ensure that the connector meets design and quality standards.

08 After -sales support and continuous improvement

Establish a feedback mechanism, collect usage and suggestions, and evaluate performance. Provide technical support and training, and optimize the design according to feedback and technical progress to improve performance and satisfaction.

09 sustainable development concept

In the customized service, environmental protection materials and energy -saving technology are used to reduce the impact on the environment and achieve green manufacturing.

Quality management

01 quality management system

ISO 9001 Certification: Comprehensively implement the ISO 9001 quality management system to ensure the standardization of organizational structure, business process and resource management, and improve product quality and customer satisfaction.

Comprehensive quality policies: clear quality policies and quantitative quality goals, ensure that all staff understand and participate in quality management, and promote continuous improvement.

02 Raw material management

Supplier evaluation and screening:

Rigorous review process: strictly review potential suppliers, including the quality management system, production capacity and historical performance evaluation.

Long -term cooperative relationship: Establish long -term cooperative relationships with high -quality suppliers to ensure the stability and consistency of raw materials.

Inspection and traceability of the warehouse:

Multi -dimensional inspection: All raw materials have been detected by a number of indicators such as size, chemical composition and physical properties to ensure that it is in line with technical specifications.

Tracing management: Establish a material traceability system to ensure that each batch of materials can be traced back to the source to enhance the transparency of quality tube.

03 Process Control

Process monitoring and data analysis:

Statistical Process Control (SPC): Apply the SPC method to monitor the key production links in real time to ensure the stability of the production process and the consistency of the product.

Data -driven decision: Use data analysis tools to analyze production data in real time, quickly identify abnormalities and take corrective measures.

Standard operation program (SOP)

Detailed record: All production processes are prepared for standard operation procedures (SOP) to ensure that each employee follows the same process when performing tasks and reduce differences.

Regular review and update: regular review and update SOP to adapt to new technologies and best practices to ensure operating effectiveness.

04 Quality Inspection Process

Multi -level quality test:

Raw material inspection: All raw materials have been thoroughly tested before production to ensure that it meets the preset standards.

Online monitoring: Set online detection points in key processes, monitor the quality of the product in real time, find problems and adjust it in time.

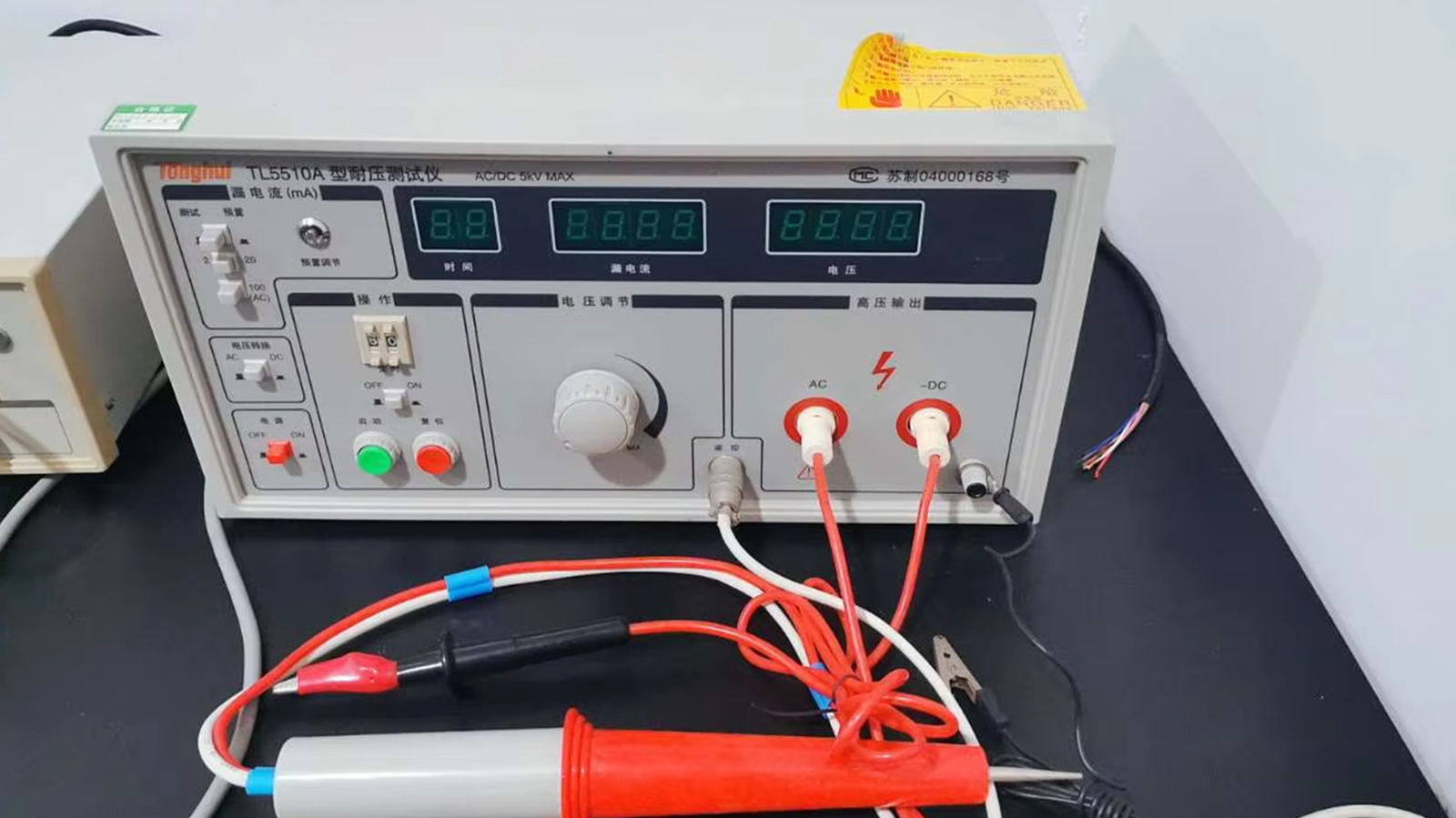

Finished product inspection: Perform comprehensive electrical performance, mechanical strength and environmental adaptability testing for each batch of finished products to ensure that it meets industry standards and customer requirements.

Laboratory test:

Certification Lab: Establish a test laboratory that meets international standards, conduct in -depth analysis and verification of products to ensure the reliability of product performance.

Independent third -party test: Entrust independent third -party institutions if necessary to test and verify product testing and verification to enhance the objectivity of quality assurance.

05 employee training and quality culture

System training plan:

Regular training: Provide systematic quality management training for all employees, including quality awareness, operational skills, and ability to solve problems.

Certification and evaluation: Implement the employee skills certification system to ensure that employees have necessary professional knowledge and operational ability.

Quality and cultural construction:

Incentive mechanism: Establish a quality improvement incentive mechanism, encourage employees to make suggestions for improvement, and participate in quality management.

Cross -departmental collaboration: promote communication and cooperation between departments, and jointly promote the realization of quality management goals.

06 Customer feedback and continuous improvement

Customer satisfaction evaluation:

Structural survey: regularly carry out customer satisfaction surveys, use quantitative indicators to analyze customer feedback, and provide a basis for product and service improvement.

Customer complaint handling: Establish a fast response mechanism to deal with customer complaints in a timely manner to ensure that the problem is effectively resolved and analyzed.

Continuous improvement process:

Fundamental cause analysis (RCA): Analyze the root cause of the problem, ensure that the problem is completely solved, and prevent similar problems from happening again.

PDCA cycle: adopt a plan-execution-inspection-processing (PDCA) cycle method to continuously optimize the quality management process and product quality.

07 Internal Audit and Management Review

Regular internal review:

Audit plan: Formulate the annual internal audit plan, the effectiveness and compliance of regular review of the quality management system, and identify potential risks and opportunities for improvement.

Report report: Write a detailed review report to provide management decision support to ensure the continuous adaptability of the quality management system.

Management review:

High -level participation: Regularly hold a management review meeting, analyze the current status of quality management and improve suggestions, and ensure that resource allocation is consistent with corporate strategies.

Objective assessment: Evaluate quality goals, formulate the next step quality improvement plan, and promote the sustainable development of enterprises.

Quality management is a systematic and comprehensive process, covering all aspects of raw material procurement to after -sales service. Through strict quality control and sustainable improvement mechanisms, ensure that each product meets international high standards, enhances customer satisfaction, and promotes the sustainable development of the enterprise.

Detection equipment

Factory core value

High quality: We always put quality first. From professional R & D design to every step of strict control of the production process, to ensure that our connector can withstand bad conditions such as extreme temperature, vibration, and corrosion, and can provide stable and reliable connections. Base.

Innovative R & D team: We lead the team to continue to explore in the technical field, always pay attention to customer needs, ensure that our products maintain a leading position in technology, and help customers achieve business goals. Confidentiality cooperation: We attach great importance to customer business secrets and brand image. We promise to be absolutely confidential, strictly abide by the contract agreement and intellectual property law, and ensure that the design and product information of the customer must be safe and not leaked to the third party.

We designed high -quality products that meet market expectations around the needs of customers. Through in -depth understanding of user feedback, we are committed to transforming innovative ideas into feasible product solutions to help customers solve practical problems.

Professional technical support: Provide comprehensive technical support during the customization process. Our engineers cooperate closely with customers to ensure that every detail meets the expectations of customers, and provides necessary technical guidance during installation and use.

Establish long -term relationships with customers. We care about their success and development, from product development and technical support to providing special project teams to ensure smooth implementation and efficient delivery. We believe that mutual benefit and mutual trust partnerships are the key to win -win, whether our customers are brand owners, designers, importers or entrepreneurs.

You can also contact us directly in the following ways: visit, telephone, email