M12 connector as a widely used connector in the field of industrial automation, its selection often needs to consider many factors. To help you choose the most suitable M12 connector product, we have detailed the key parameters:

M12 connectors are available in straight, right Angle and elbow types, depending on the mounting form of their housing. The straight-head M12 connector is easy to install, takes up less space, and is suitable for narrow environments. The rectangular M12 connector has a horizontal layout, which is also suitable for installation in small Spaces. The elbow type M12 connector allows for easy cable wiring. The appropriate connection type should be determined according to the actual installation environment and cable direction.

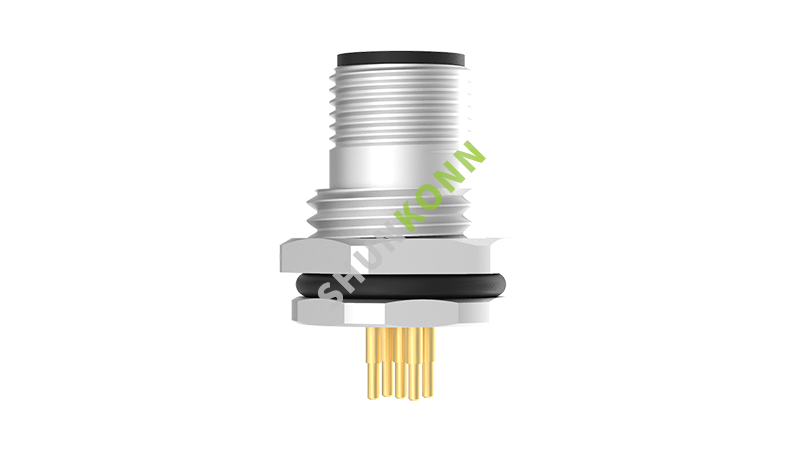

M12 connectors are usually available with different pin numbers such as 3, 4, 5, and 8. The choice of the number of pins depends on the number of signals or power supplies that need to be transmitted. For example, the 4-core M12 connector is suitable for transmitting four independent signal channels, while the 8-core connector can meet the needs of simultaneously transmitting multiple signals and power supplies. Users need to determine the appropriate number of contact points according to the specific system structure and functional requirements.

To prevent insertion errors, the M12 connector uses different polarity codes such as A, B, D, and X. The code selection needs to match the code of the device interface to ensure the correctness of the connection. Be sure to pay attention to the coding requirements of the device to be connected when selecting the model.

M12 circular connectors are available in different current rating (4A, 6A, 16A, etc.) and voltage (60V, 250V, etc.) specifications. Users need to select the appropriate M12 connector according to the current and voltage parameters of the signal or power supply in the actual application environment. Too low a rating may cause problems such as overheating at the joint, while too high a rating increases costs.

M12 connectors can be divided into IP65, IP67, IP68 and other grades according to their dustproof and waterproof performance. The IP65 class protects against dust entry, the IP67 class protects against brief immersion, and the IP68 class withstands long-term immersion. Users need to select the protection level according to the environmental conditions of the application site.

M12 connector housing and pins are usually available in metal (stainless steel, brass, etc.) and plastic (PA, PVC, etc.) materials. Metal material is more durable, but the cost is higher; Plastic material price is relatively cheap, but chemical corrosion resistance is weak. The corrosion of the use environment and the cost of the product should be weighed in the selection.

Common M12 connector certification standards include UL, CE, ROHS, etc. Users need to select M12 connectors that meet the corresponding standards according to the specific requirements of product application scenarios. This helps to ensure the safety and applicability of the product.

In addition to the above basic parameters, in some special applications, the M12 connector also needs to meet the vibration resistance, temperature resistance, radiation resistance and other requirements. Users should make targeted choices based on the characteristics of the actual use environment.

To sum up, many factors need to be considered when selecting the M12 connector to ensure the applicability and reliability of the product. The choice of a single parameter is far from enough, users need to carry out a comprehensive evaluation and trade-off according to the needs of the actual application, in order to select the best M12 connector products.

You can also contact us directly in the following ways: visit, telephone, email