Learn more about the features of the M12 circular connector

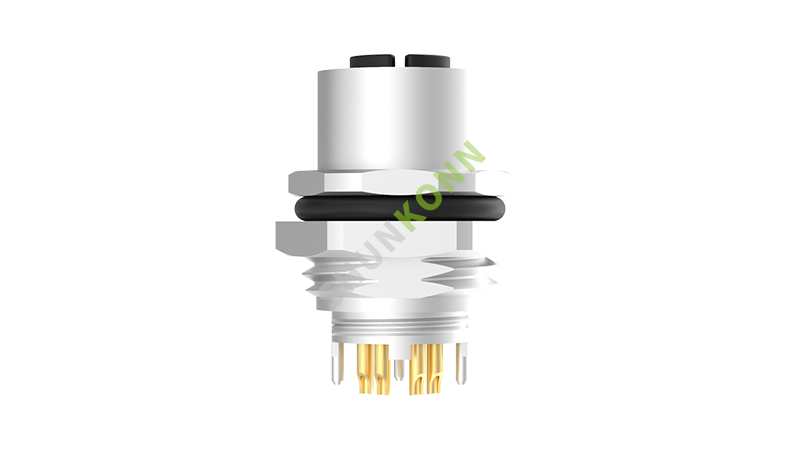

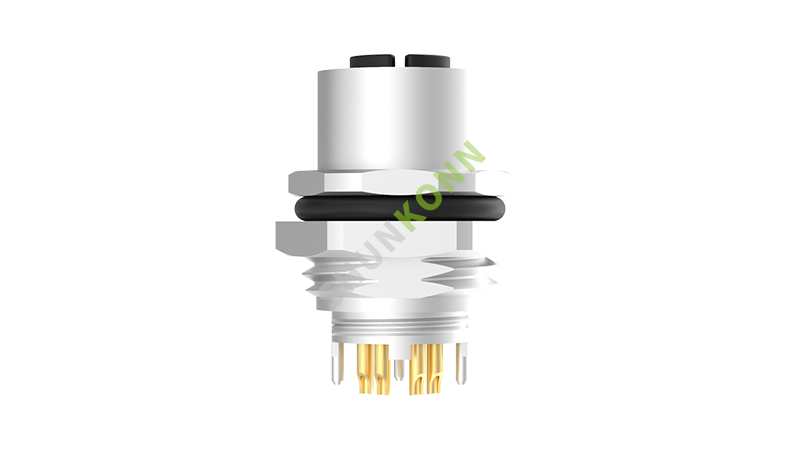

With its compact, robust design, the M12 circular connector is one of the preferred connectors for industrial automation, sensor networks, communication equipment and other fields. It not only has superior performance, but also can meet the needs of various complex environments. This article will start with its key features and take you through the unique advantages of the M12 circular connector.

1. Compact design, suitable for various scenarios:

The M12 connector has a circular, miniaturized design with an outer diameter of just 12 mm, making it ideal for space-constrained installation requirements. For example, in smart manufacturing devices, automated robots and sensor networks, it can be deployed flexibly, saving space while maintaining excellent connectivity performance.

2. High protection level, adapt to harsh environment:

- M12 connectors are usually IP67 or IP68 protected, with water and dust resistance.

- In humid, dusty environments, it can maintain a stable connection.

- For outdoor applications, such as traffic equipment or photovoltaic systems, it can effectively resist the intrusion of rain, moisture and pollutants to ensure long-term operation.

3. Strong electrical performance:

- Current and voltage support: M12 connectors are typically rated in the 2A to 4A current range and up to 250V voltage range, suitable for low to medium power signal and power transmission needs.

- Low contact resistance: Excellent contact resistance ensures signal stability and reduces energy loss.

- Low contact resistance: Excellent contact resistance ensures signal stability and reduces energy loss.

4. Diverse coding options:

M12 connectors are available in A variety of encoding types (such as A, B, C, D, X encoding) to suit different application requirements:

- A code: Used for sensor signal transmission and standard industrial connections.

- B code: Suitable for industrial Ethernet devices.

- C code: Optimized for DC power transmission.

- D code: Supports high-speed industrial Ethernet communication (up to 100 Mbps).

- X-coding: Designed for ultra-fast Ethernet applications, supporting data transfers of up to 10 Gbps.

Different coding designs avoid misconnection and improve device security and compatibility.

5. High quality material, improve reliability:

M12 connectors are commonly used in high-strength metals and engineering plastics:

- Shell material: mostly nickel-plated copper or stainless steel, with corrosion resistance and impact resistance.

- Insulation: UL-certified flame retardant materials (such as PA66) ensure stability in high temperatures and complex environments.

- Shielding performance: Some M12 connectors offer a shielding structure that significantly reduces electromagnetic interference (EMI) and ensures signal transmission integrity.

6. Convenient installation, wide application range:

The M12 connector supports a threaded locking design for easy and secure installation.

- Fast installation: The standardized design allows it to be quickly matched with a variety of devices, greatly reducing wiring time.

- Durability: The service life usually exceeds 500 times, which is suitable for frequent maintenance and replacement.

7. Wide range of applications:

Due to their reliability and versatility, M12 connectors are widely used in:

- Industrial automation: Connecting sensors, actuators and control devices.

- Traffic system: Used for train communication, signal lights and vehicle detection equipment.

- Energy industry: Used in photovoltaic power generation systems and wind energy equipment.

- Network communication: Supports industrial Ethernet and high-speed data transmission.