Today's industrial automation equipment is increasingly complex, and the signals and power supplies that need to be connected are more and more complex. The traditional rectangular connector is difficult to meet the increasingly demanding requirements, while the circular connector has become the "universal interface" in factory automation, robotics and other fields by virtue of its unique design advantages.

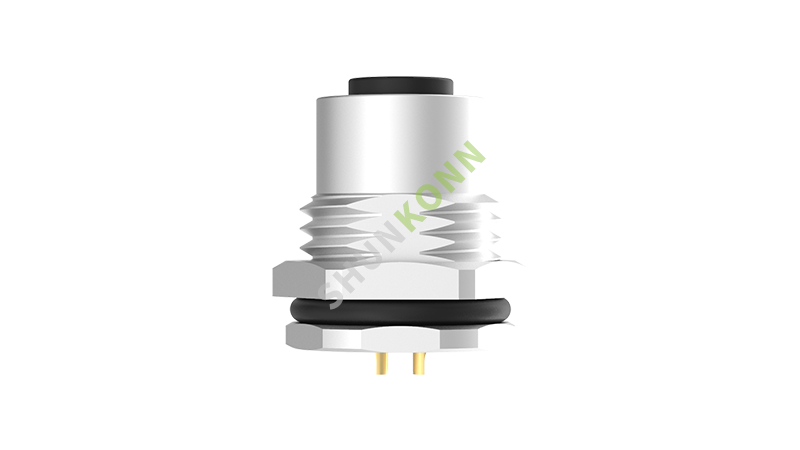

The circular connector is more compact and easy to install in a small space with an embodded terminal. At the same time, its shell is cylindrical, not only beautiful and generous, but also can better adapt to the curved structure of the surface of the equipment. In addition, the circular connector also has the flexibility of rotating connection, which greatly enhances the wiring freedom of the device.

The circular connector provides strong load-bearing performance while maintaining a small form factor. Its shell materials are mostly wear-resistant metal or plastic, can withstand up to IP68/IP69K level of protection, even in harsh environments can maintain reliable sealing. At the same time, its internal high quality cable and terminal, also can support up to tens of amperes current load capacity.

With excellent protection performance and carrying capacity, circular connectors are widely used in various equipment in industrial automation, robotics, transportation and other fields. For example, industrial robots on the factory floor need to connect a variety of complex sensors, actuator signals, and high-power power supplies, and circular connectors are the only choice. Another example is intelligent urban rail train, which puts forward higher requirements for safe and reliable on-board electrical connection, and circular connectors can also be easily qualified.

With the deepening of industrial automation, the demand for connection technology of all kinds of equipment will become increasingly diversified. We expect that the new circular connector, with a more compact and flexible design and stronger load-bearing performance, will be more widely used in the near future and become the "standard accessory" in factory automation, intelligent transportation and other scenarios.

In short, with its excellent design flexibility and strong performance bearing capacity, circular connectors are becoming an indispensable "universal interface" for industrial automation equipment. In the future, with the continuous promotion of intelligent manufacturing and digital transformation, this new high-performance connectivity technology will shine in a wider range of fields, helping industrial equipment to achieve safer and more reliable intelligent interconnection.

You can also contact us directly in the following ways: visit, telephone, email