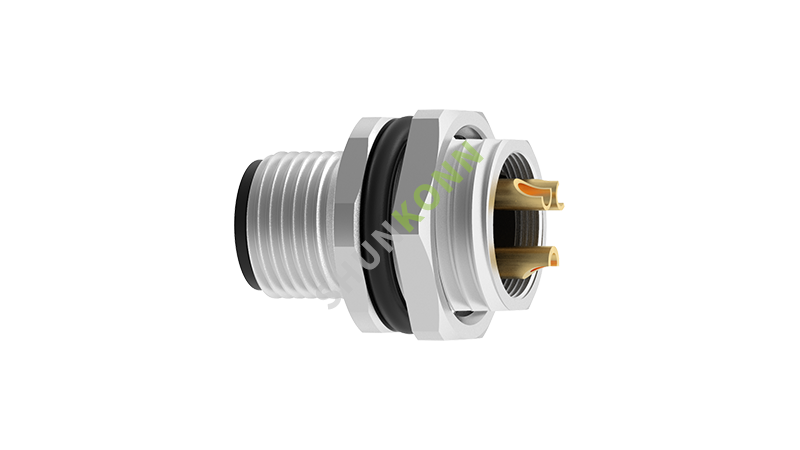

M12 connector is a widely used interface standard in the field of industrial automation, and its installation mode directly affects the flexibility and appearance of use. For the M12 connector front and back board installation, let's take a comprehensive look.

In Rear-facing nut installation, the housing of the M12 connector is fixed directly to the panel or front of the case of the device. The front part of the connector will be exposed on the outside of the panel, which is convenient for users to connect and disconnect at any time. This installation is ideal for situations where frequent connections are required.

Specifically, the rear end part of the M12 connector mounted at the front of the board will pass through the panel and be fixed to the rear side of the panel. When installing, it is necessary to open a hole of the right size on the panel, and then fix the shell of the connector to the panel by means of nuts or clasps. In this way, the front end of the connector can be directly exposed to the outside of the panel for the user to use.

The main advantages of this pre-board installation are:

Connecting and disconnecting is easier. Since the front end of the connector is exposed, users can perform connection operations at any time without removing the panel. This is ideal for situations where you need to plug and unplug frequently.

Easy to maintain and repair. In the event of a problem, the connector can be quickly found and replaced, improving the maintainability of the device.

Of course, there are some limitations to pre-board installation:

Takes up more panel space. The connector housing can penetrate the panel and take up more front panel space, which may affect the overall appearance of the device.

Potential safety hazards. Because the front end of the connector is exposed, there may be some security risks, and protective measures need to be taken.

In contrast, Front-facing nut places the entire M12 connector housing on the rear side of the device panel. In this case, the front end of the connector will only expose a ring mounting slot for connection to the corresponding male head.

For specific installation, it is only necessary to cut a hole of suitable size in the panel, and then insert the connector from the back and fix it. In this installation mode, the connector is completely embedded in the back side of the panel, only the front end is visible, and the overall effect is more beautiful and compact.

The main advantages of the rear board installation method are:

More beautiful and compact. Because the connector shell is completely hidden behind the panel, the overall appearance is more neat and beautiful, in line with the aesthetic requirements of modern industrial equipment.

Higher security. The front end of the connector is obscured by the panel, which greatly reduces security risks.

However, there are some limitations:

Connecting and disconnecting is a little inconvenient. Since the front end of the connector is occluded by the panel, the user needs to connect through the panel opening, which is not as convenient as the installation in front of the board.

Maintenance and overhaul are inconvenient. If there is a problem, the panel needs to be removed to carry out maintenance, which is relatively complicated to operate.

In summary, the M12 connector has its own advantages and disadvantages for both front-board and back-board installation. Users can select the appropriate installation mode based on specific application scenarios and requirements. When frequent disconnection is required, pre-board installation is more suitable; And when the pursuit of beautiful and compact appearance, board installation is a better choice. Most M12 connectors support both types of installation, providing users with flexible options.

You can also contact us directly in the following ways: visit, telephone, email