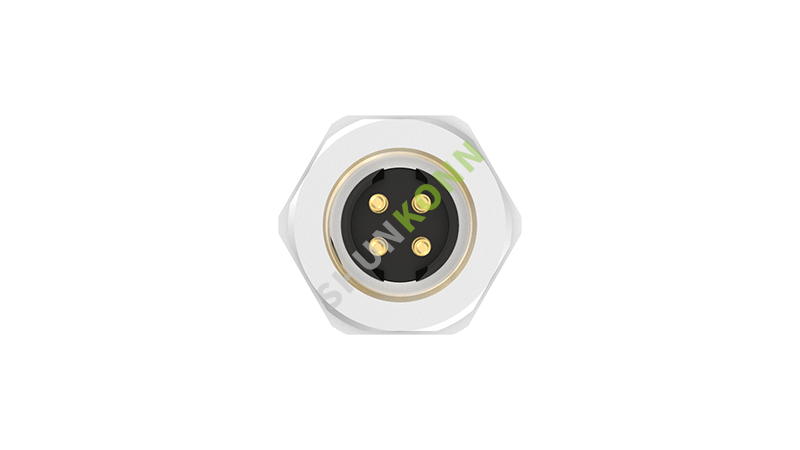

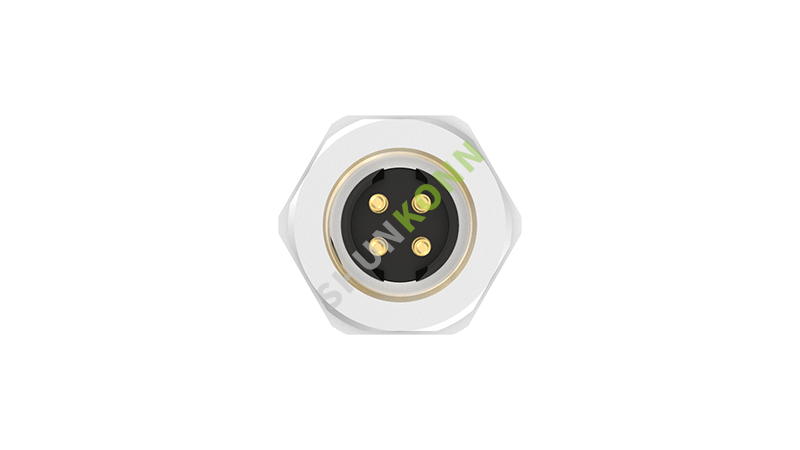

M12B coded connector board rear-mount soldered socket is a key interface component for industrial automation and network communications, and is designed for harsh environments and efficient transmission with several significant benefits.

1. B coding design

- ADAPTS to industrial Ethernet (such as PROFINET and Ethernet/IP) to ensure high-speed and stable signal transmission.

- The stay-proof structure effectively prevents incorrect insertion and removal and improves connection reliability.

2. Weld and install the rear board

- Compact layout: The connector is hidden on the back of the board to save device space.

- Stable and fixed: welding installation to avoid vibration and shock caused by loosening.

3. Excellent protection performance

- IP67/IP68 rating: dustproof and waterproof, suitable for harsh industrial environments.

- Shielding design: resist electromagnetic interference, ensure signal integrity.

4. Reliable electrical performance

- Rated voltage 250V, current 5A, to meet a variety of industrial needs.

- Voltage resistance up to 1500V, contact resistance as low as 5mΩ, improve system efficiency.

5. Durability and safety

- Supports more than 500 insertions and removals for a long service life.

- Wide temperature range: -40℃ to +80℃ for fixed installation, -20℃ to +80℃ for flexible installation.

- UL94 V0 flame retardant grade, safe and reliable material.

6. High quality materials

- Copper nickel-plated housing: resistant to corrosion and mechanical stress.

- PA66 + GF insulation material: High heat resistance and mechanical strength.

M12B coded connector board rear-mounted welded plate socket is the preferred solution for industrial automation and networking equipment due to its high reliability, strong anti-interference capability and excellent protection performance. In the selection, according to the equipment requirements and environmental conditions to select the appropriate specifications and models to ensure the efficient and safe operation of the system.