In today's industrial automation equipment with each passing day, the performance of connectors has become the key factor to win. M16 and M12, as two mainstream industrial connectivity standards, are engaged in a fierce "dragon tiger competition" with their unique advantages.

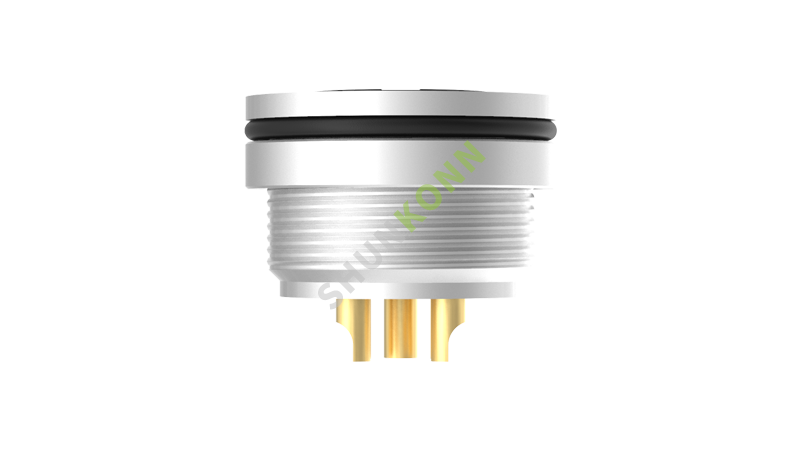

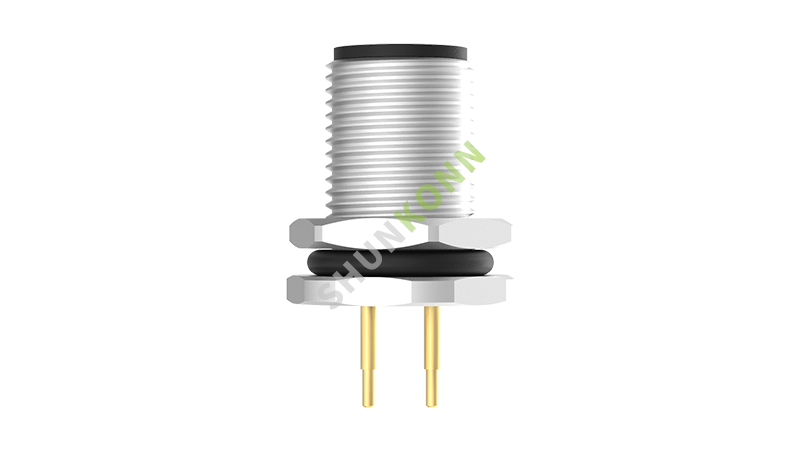

The M16 connector has a housing diameter of 16mm, compared to 12mm for the M12. This slightly bulkier shape allows the M16 to offer a greater number of pins, up to 24 contact points. The M12 has a maximum of 17 stitches. This brings more powerful signal and power transmission capabilities to the M16, giving it an advantage in complex industrial control and fieldbus applications.

Both M16 and M12 can meet IP67 dust and water standards. However, the M16 can also choose higher IP68 and IP69K protection levels, which allows it to maintain excellent protection in harsh conditions such as water, high-pressure steam cleaning and other scenarios. In contrast,M12's protection is relatively limited. For some factory workshop, outdoor work and other harsh environment of automation equipment,M16 strong protection ability is undoubtedly better.

M12 adopts the traditional thread type fixation method, while M16 provides a more flexible and convenient interface type, spring lock and other fast connection solutions. This gives M16 a stronger advantage in equipment maintenance and upgrading, greatly shortening the maintenance and transformation time. This feature of the M16 is particularly critical for automation equipment that requires frequent maintenance.

The M16 also outperformed the M12. Its internal structure is specially designed to withstand impact forces of up to 25g and maintain reliable signal transmission in strong vibration environments. This makes M16 very suitable for application in high-speed CNC machine tools, robots and other automation equipment.

More importantly, the M16 connector has an excellent modular design. Its detachable interface structure enables rapid disconnection and reconnection, greatly improving the convenience of device maintenance. At the same time, the M16's modular nature also supports rapid plug and play replacement, providing great flexibility for equipment transformation and upgrade.

To sum up,M16 and M12 industrial connectors each have unique advantages. The M16's compact size, strong protection, fast connection, excellent seismic resistance and modular design give it an advantage in complex and harsh industrial automation environments. However, M12 is more suitable for scenarios that are more sensitive to space and cost.

With the advent of Industry 4.0 era, factory automation equipment will face more challenges. M16 connector with its excellent functional features, will undoubtedly become an important force to promote the continuous progress of this field. It is believed that M16 will play an increasingly important role in the industrial automation market in the near future.