Robot control system uses circular connectors

Case background

A leading global robot manufacturing company focused on the development of high-precision robots for automated production lines. With the increasing demand for automation solutions, the company wants to improve the connection stability and data transfer efficiency of its robot control systems to support more complex operations and real-time monitoring.

Customer challenge

After conducting market research and internal testing, the customer found that its existing connectors were significantly inadequate in the following areas:

Signal interference: Because the robot operates in a high-density wiring environment, the original connector is vulnerable to electromagnetic interference (EMI), resulting in unstable signal transmission, which affects the control accuracy and response speed of the robot.

Connection reliability: Frequent connection and disconnection operations cause contact point wear, increase the risk of connection failure, and affect the overall reliability of the device.

Space limitation: The design of the robot control system requires that the connector has a smaller volume to accommodate the compact installation space, and the original connector cannot meet this demand.

solution

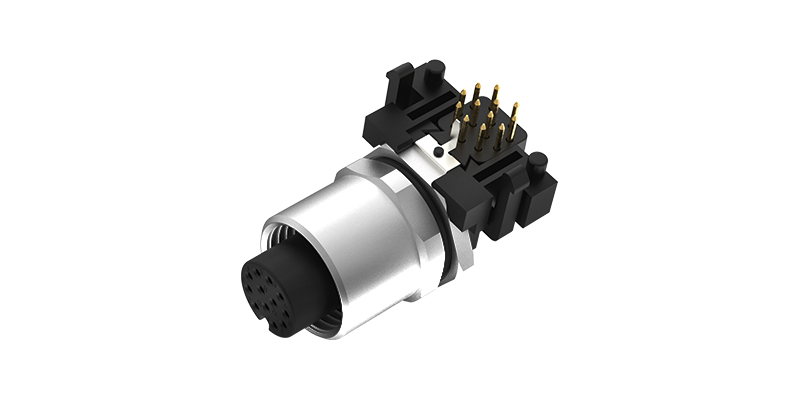

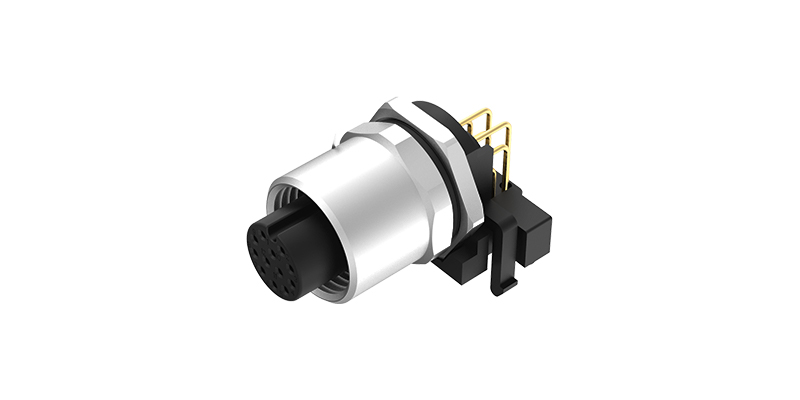

In response to the challenge posed by the customer, the SHUNKONN engineering team conducted an in-depth requirements analysis and designed a new miniaturized M12 circular connector.

Design features of the connector include:

High shielding design: Multi-layer shielding material is used to significantly improve the ability to resist electromagnetic interference and ensure stable signal transmission in complex environments.

Wear resistant contact points: The use of highly conductive alloy materials and optimized contact point layout enhance connector durability and ensure high reliability during frequent insertion and removal.

Compact construction: The M12 connector is designed with space constraints in mind and is small enough to be easily wired in a tight mounting space.

Achievement and influence

The implementation of SHUNKONN circular connectors has enabled customers to achieve significant improvements in their robot control systems in a number of areas:

Improved control accuracy: By reducing signal interference, the response speed and control accuracy of the robot when performing high-precision tasks are greatly improved.

Enhanced system reliability: Optimized contact point design reduces connection failure rates, improves overall system reliability, and reduces maintenance costs.

Market competitiveness: The performance of customers' products has been significantly improved, making them stand out in the fierce market competition and winning the trust and orders of more customers.

This success demonstrates SHUNKONN's expertise and innovation in the field of robot control systems and demonstrates our commitment to providing our customers with efficient and reliable connectivity solutions to meet changing market demands.

# Circular connector #M12 connector # Electromagnetic interference (EMI) # data transmission # control system # automated production # Signal integrity # high-precision operation # Connection reliability

Contact us for a quick quote and get free technical answers from our technical team.

You can also contact us directly in the following ways: visit, telephone, email