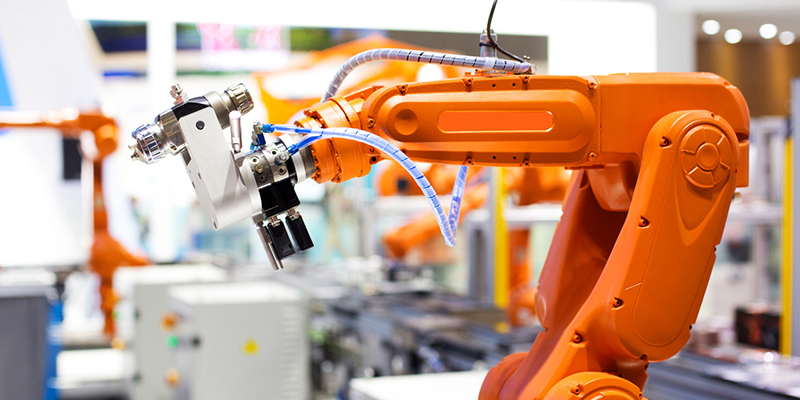

Industrial robot connector success story

Case background

Industrial robot manufacturers want to improve the maintainability of their products, in particular by requiring connectors that can be quickly connected and disconnected to support frequent field operations. This demand is designed to reduce equipment downtime and increase production efficiency while reducing maintenance costs.

Customer Challenge:

Low maintenance efficiency: The insertion and removal process of the original connector is complicated, requiring professional tools and a long time, which affects the flexibility of field operation.

Insufficient connection stability: Due to frequent connection and disconnection, the original connector is prone to poor contact, resulting in unstable electrical connections of the robot in high-frequency operations.

Poor vibration resistance: In high vibration environments, the reliability of the original connector is insufficient, increasing the risk of equipment failure.

solution

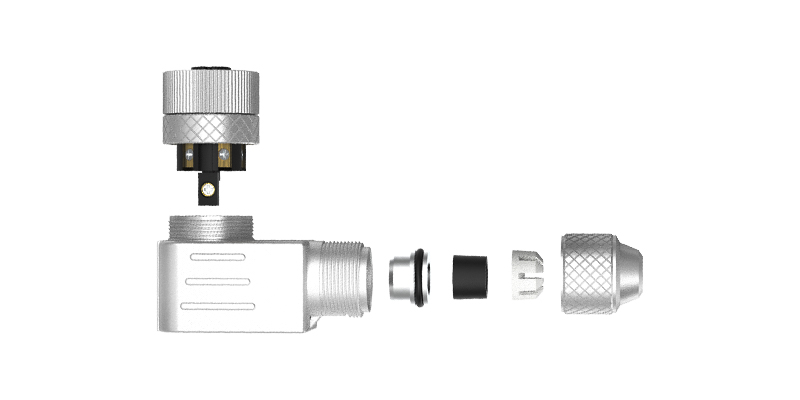

SHUNKONN's engineering team has developed and launched a quick-connect circular connector.

Design features of the connector include:

One-button plug design: The connector adopts a simple and intuitive fast connection mechanism, and the user can complete the connection and disconnect with just one click, greatly reducing the maintenance time and labor costs.

Wear-resistant materials: The use of high-strength wear-resistant materials to ensure stable electrical connections in high-frequency operations, improving the service life of the connector.

Enhanced vibration resistance: Anti-vibration characteristics are considered in the design to ensure that the connector can withstand high vibration environments without failure during the operation of industrial robots.

Achievement and influence

The implementation of the new SHUNKONN quick-connect circular connector has enabled customers to achieve significant improvements in their industrial robots in a number of ways:

Improved maintenance efficiency: The one-click plug and pull design significantly reduces maintenance time, and field operators can quickly complete the connection and disconnection, improving work efficiency.

Improved connection stability: wear-resistant materials and enhanced vibration resistance ensure the stability of electrical connections in high-frequency operations, reducing failure rates.

Reduced operating costs: Due to the reduced maintenance frequency, the customer's overall operating costs have been effectively controlled, and the reliability of the robot system has been significantly improved.

This success demonstrates SHUNKONN's expertise and innovation in the field of industrial robotics, underlining our commitment to providing our customers with efficient and reliable connectivity solutions to support the development of modern manufacturing.

# Industrial robots # Fast connectors # Maintainability

Contact us for a quick quote and get free technical answers from our technical team.

You can also contact us directly in the following ways: visit, telephone, email